In Australia, thousands of lighting fixtures (luminaires) are secured into place in a similar way – they are attached to the roof using galvanised bolts connected to aluminium luminaires.

Challenge

Our client challenged us to replace 3000 light brackets in one of the busiest tunnels in Australia, with minimum shutdowns – a process that would normally take years and be very costly.

Solution

Our team developed an innovative, secondary safety mechanism that eliminated the need to replace the luminaires, and completed the project in one night.

Impact

Saving costs and time for our client, this innovation has the potential to change design and installation standards for future tunnel construction and maintenance.

When you pass through a traffic tunnel, have you ever looked up at the lights?

A tale of two metals

Separately, both materials are excellent at preventing corrosion. However, when brought together in the presence of an electrolyte (water), the two different metals cause the galvanised bolts to corrode into powder. This is called bimetallic corrosion.

Visual detection of the corrosion is challenging as the bolts are obstructed from view under a flat U-bracket. As a temporary fix, luminaires are often strapped to a supporting structure, which not only looks untidy, but makes them difficult to access making it unsustainable solution.

The challenge

Our client challenged us to replace all 3,000 brackets in one of Australia’s busiest tunnels with minimum shutdowns per year.

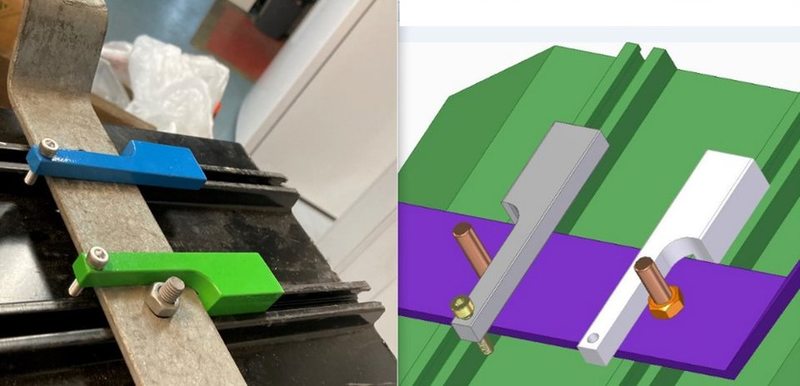

Enter: the MTBolt. An engineered solution that eliminates the need to replace the luminaires.

A bolt from the blue

Manufactured in aluminium so bimetallic corrosion doesn’t occur, the MTBolt’s design easily slides over the supporting U-bracket. It locks the bracket to the luminaire body and provides nine times the increased contact surface area for better stability.

While one MTBolt easily supports a 29kg luminaire, plus an additional tested load of 85kg, installing four across the U-bracket provides a complete secondary safety mechanism with four failsafe points.

The MTBolt is $12 worth of engineered safety, protecting installers and commuters and easily adaptable for tunnels built in the last 15 years with similar luminaires.

The simplicity of the MTBolt is its greatest innovation. Designed to slide over the current U-bracket means there is no need to dismantle the luminaire or any of its supporting framework. This not only saves time (average 40 minutes, down to two minutes), but also reduces the personal risks for each maintenance crew member.

While the MTBolt won’t have an immediate impact like the smartphone or AirPods, it has the potential to change lives across the globe. With a concept so incredibly simple, this innovation:

- provides the most effective solution to mitigate the risks associated with bimetallic corrosion in luminaires in any tunnel built in the last 15 years

- has the potential to change design and installation standards for future tunnel construction and maintenance.

The result is the safeguarding of both workers and commuters, without incident.

AFR Most Innovative Companies 2023

Ventia was recognised in the 2023 AFR Boss Most Innovative Companies List as third in the property, construction & transport category for our MTBolt innovation.

At Ventia, we are obsessed with doing things better than we have ever done them before. We work closely with our clients and partners to solve problems and create opportunities. And we invest time with our internal teams and partners to change the future by looking at improvements through our people, processes and technology.