In conversation with

Dimity Agland

Dimity Agland leads Business Development for Ventia’s Rigs & Wells business unit. With more than 10 years in the industry she has deep knowledge of our operations and the broader market

To meet the investment in low emissions and critical technologies it is estimated that global demand for critical minerals needs to increase by 350% between now and 2040*.

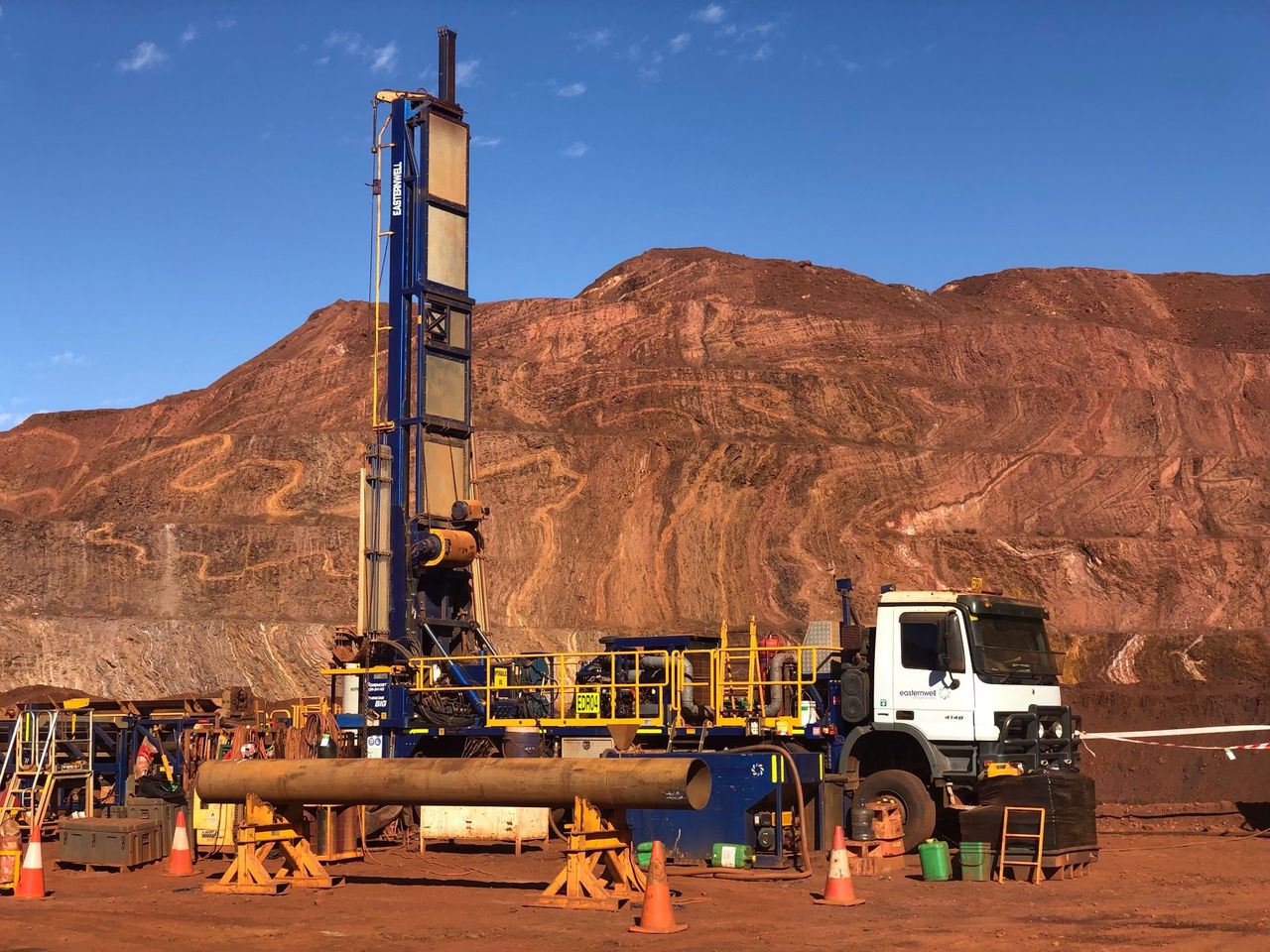

With Australia set to be a key link in the global energy transition supply chain for years to come, Ventia’s Rig and Wells team will continue to be a critical partner to minerals, energy and metals clients right across Australia’s resources industries.

As a leader in the Rig and Wells team Dimity Agland shares her thoughts on what she is seeing across the industry and how the Ventia team is well placed to support this demand.

Q. What are some of the trends you see happening across the industry and our Rig and Wells business?

Clients have been increasing production targets and shifting greater focus on drilling deeper wells to access additional gas supply. Supply drops far earlier than the demand, creating a need for additional energy drilling rigs and dual rotary rigs. There’s also a big focus on technology and emissions reduction as clients seek more efficient ways of operating.

Emissions reduction

Emissions reduction is a key focus right across the industry. We’re investing in new generators on our well servicing rigs which is reducing CO2 emissions as well as delivering cost savings through a reduction in fuel consumption.

A key factor in our sustainability agenda is about ensuring our equipment is functioning to the best of its ability. We identified the need to replace existing rig and airpack generators on three of our rigs that were reaching its end of life. This was an opportunity to swap with more efficient models, in turn, reducing the amount of diesel used by approximately 31%.

We’re also implementing trials with some clients to introduce electronic monitoring systems to track emissions, asset health and drilling conditions.

Through our gas operations, there is a real focus on reduction of methane and diesel emissions. Our team is aiming to be part of the solution and are researching different power generation replacement solutions including methane capture, battery powered systems and ammonia and hydrogen fuel cells. We’re still in the research phase but we want to be at the forefront of solutions design.

Safety

Safety is always number one and we will always strive for continuous improvement. This not only relates to the job site itself, but also to the wellbeing of our people more broadly. One thing that has been a focus across the industry in recent time has been around fatigue as it relates to travelling in remote environments.

In 2023 Ventia, in conjunction with our client, was able to fit fatigue monitoring systems to light vehicles across some of our operations as a way to mitigate this risk. These systems monitor driver behaviour by monitoring facial expressions for distractions, excessive blinking or the closing of their eyes. When it picks up one of these events has occurred, it alerts the driver either by audible alarms or vibrating their seat to get their attention and sends a recording of the event to the leadership team in town to review and provide support where required.

With this system now implemented the team will look to extend this initiative across other more operations, in consultation with our clients, for the benefit of our people.

Our minerals team is also working with clients on improving safety through removal of the driller from the immediate area. The early foundations are in place with the next stage being the installation of a remote system where our rig can be operated away from the drill spot, whilst ensuring we can always monitor pressures and controls in critical functions.

Diversity and inclusion

We are actively working to have more women in our blue-collar positions. A big part of inclusion is not only recruiting but retaining and we have been successful in employing and retaining a number of women in leasehand positions on our workover operations.

One of the ways we know can assist in helping us to diversify our workforce is making our sites places where people who traditionally haven’t worked in remote operations are comfortable. This includes the introduction of better onsite facilities and well as internal audits on a range of things including security and amenities.

More generally we’re working to ensure that opportunities exist for progression and also bringing young people into the workforce through apprentices at our Withcott workshop.

Introduced onsite toilet facilities to our mineral operations with BHP which was able to increase attraction for both male and female workers. Completed internal audit on all rig camps to ensure adequate security & amenities was provided for women working in the industry.